Wood Light Frame Construction History

Wood light frame construction was the first uniquely American building system. It was developed in the first half of the 19th century when builders recognized that the closely spaced vertical members used to in all the walls of a heavy timber building frame were themselves sufficiently strong that the heavy posts of the frame could be eliminated.

Its development was accelerated by two technological breakthroughs of the period: Boards and small framing members of wood had recently become inexpensive for the first time in history because of the advent of the water-powered sawmill; additionally, machine-made nails had become remarkably cheap compared to the hand-forged nails that preceded them.

The balloon frame was the earliest wood framing system to be constructed exclusively of slender, closely spaced wooden members: joists for the doors, studs for the walls, rafters for the sloping roofs. Heavy posts and beams were completely eliminated and, with them, the difficult, expensive mortise-and-tenon joinery they required. There was no structural member in a frame that could not be handled easily by a single carpenter, and each of the hundreds of joints was made with lightning rapidity with two or three nails. The impact of this new building system was revolutionary:

In 1865, G. E. Woodward could write that the man and a boy can now attain the same results, with ease, that twenty men could on an old-fashioned frame the Balloon

Frame can be put up for forty percent less money than the mortise and tenon frame.

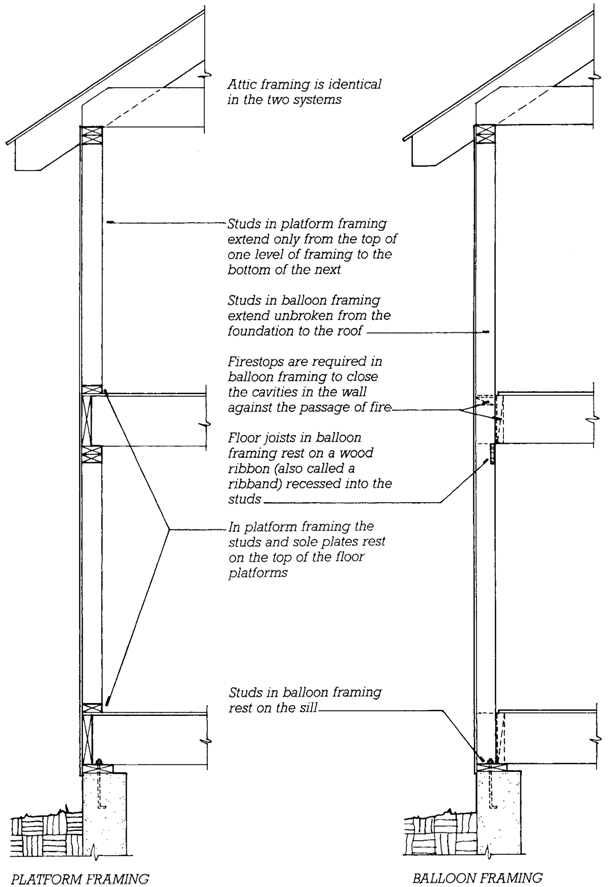

The balloon frame (Figure 5.2)

used full-length studs that ran continuously for two stories from foundation to roof. In time, it became apparent that these were too long to efficiently. Furthermore, the tall, hollow spaces between studs acted as

Figure 5.2

Comparative framing details for platform framing (left) and balloon framing (right).

Platform framing is much easier to erect and is the only light framing system used today. However, a platform frame settles considerably as the wood dries and shrinks.

If nominal 12-inch (300-mm) joists are used to frame the floors in these examples, the total amount of loadbearing cross-grain wood between the foundation and the attic joists is 33 inches (838 mm) for the platform frame and only 4½ inches (114 mm) for the balloon frame.