History

It is entirely probable that vegetation, in the form of turf, grasses or another material formed the roofs of the first buildings. Radiocarbon dates suggest that the first agricultural communities crossed to Britain from the European land mass c.4,000 BC, bringing with them seed corn for wheat, barley and flax and it is not unlikely that that thatching with corn straw might date from this time. Assuming that houses were thatched (no definite archaeological evidence has been found for this, the assumptions are based on logic and experiments in reconstruction), by the Iron Age there must have been people competent at thatching; footprints have been found of Iron Age ’round houses’ up to 17 meters in diameter which shows a confidence in being able to ‘heal’ roofs well.

The Anglo Saxon word thaec originally meant to roof with any material; the commonest roofing materials were vegetation, so eventually thatch came to have its modern meaning. The materials used would have depended on local availability and cost; bracken, broom, sedge, heather, hazel twigs were all used though eventually straw from wheat, oats, rye or barley predominated in southern and western England, water reed in eastern England and heather in the north and Scotland. Exceptions existed within this pattern such as heather or broom in the heathland areas of Kent and Surrey, and reed in parts of Hampshire and Dorset. Hambrook Barn at the Museum was originally thatched with local esturine reed.

Early documentary references exist also. In 450 AD Bede wrote of the fire that broke out when St German visited the tomb of St Alban, noting that the houses that burnt were covered with ‘marsh reed’. Later building accounts give information about materials, prices, labour and show the extent to which thatch was used. In 1283 accounts for Dover Castle state that 3s 4d was paid for ‘500 sheaves of stubble for thatching the well house in the keep, the wash house and the house in which Simon the clerk lives’. Repairs to the barn at Farnham Rectory in 1472 involved paying for ‘four score threfe of winter corn straw, 6s 8d. To John Rote for drawing (preparing) the said straw 10d … to William Pepylton for thatching 5 days, 2s 1d‘. A threfe is a measured bundle of straw (the term ‘thrave’ is still used) and winter corn straw is that which has been threshed and stored). In 1208 ’28 bundles of rods and 1500 withies (wands of willow) for pinning and tying down the thatch’, costing 4s 2d, were bought for Pevensey Castle and in Gravesend in 1367, the receipt of 1500 rods and 3000 sprendles is mentioned in accounts. Rods (or sways) are 2½ – 3′ lengths of wood (usually coppiced hazel) that hold down laid rows of thatch, ‘sprendles’ are probably spars, twisted wooden staples (again usually hazel) used to pin down bundles of thatch and rods (for more about spar making and coppicing see the woodland crafts ‘introductions’ sheet). At this time, at least from some accounts, the term ‘reder’ indicated someone who thatched, a theccer could mean a roofer working with other materials; a 1378 account from Cambridge mentions ‘ a sclattere with his servant, a theccer with his servant, and two reders’ working on the King’s Hall. It also appears that thatchers were relatively well paid. In 1251 a thatcher in Downtown, Wiltshire was paid 6s 4d for thatching an ox shed and 16s for thatching a new barn; at this time the recommended wage for a labourer was 1s a week. No indication is given as to the size of the roof, but a modern estimate is that it takes three weeks to thatch a medium sized cottage.

Recent work by archaeobotanist John Letts has shown that thatch from the Medieval period has survived in situ in around 200 buildings in southern England. Traditionally only the surface layer was stripped back before re-thatching, leading to thatch up to 7′ thick on roofs dating from the 14th-16th

centuries. This not only reveals information about thatching practice and materials but also adds greatly to knowledge of Medieval agriculture.

As can be seen from the references above, thatch once covered the roofs of castles as well as those of lower status dwellings, farm buildings and animal sheds. This widespread use of thatch helped devastating fires spread in cities such as London, Canterbury, Winchester, Worcester and Chichester in the period 1077 – 1202 and in 1212 building regulations were issued in London stating ‘whosoever wishes to build, let him take care…that he roof not with reed, nor rush, straw nor stubble but with tile only, or shingle, or boards, or…lead or plastered straw within the city…’; the document goes on to say that any reed or rush thatched roofs must be plastered in 8 days or they would be pulled down. The regulations were probably never fully enforced; a plot to burn London down by setting poultry loose with burning firebrands tied to their legs was allegedly hatched by Simon de Montford in 1264. The 13th century, however, did see the spread of tiles as a roofing material and later great fires such as the fire of London in 1666 and a fire that nearly destroyed Wareham in Dorset in 1762 probably were the ‘last straw’ for the widespread use of thatch within towns.

Eventually, even in the countryside, a combination of factors caused a gradual decline in the use of thatch. Generally, straw was plentiful and cheap and, because it was light, it was ideal for use on less than substantial lower status buildings. This meant that it came to be seen as a low class material and there are recorded incidences of roofs being tiled on the side visible from the road, and thatched on the side hidden from public view. The wheat shortages (and subsequent high prices) caused by lack of imported corn during the Napoleonic wars (1790s – 1815) are often quoted as playing a part in the decline of thatch though for two reasons this argument may be spurious. Much pasture in Britain was turned to arable to combat the supply problems, this would make straw more plentiful, also grain was generally imported threshed, so shortages would have no impact on the supply of straw. The growth of railways made other roofing materials more accessible, especially Welsh slate in the first half of the 19th century and industrialisation caused a shift in patterns of labour and settlement, which in turn affected housing methods and materials. Through the 19th century and into the 20th thatch did retain some currency as a roofing material however; as late as 1948 E J Stowe, in ‘Crafts of the Countryside’, felt confident enough to write “straw thatching will continue as long as there are capable thatchers in a village”. The final blow for thatching was really the emergence of modern short stemmed wheats and the combine harvester in the 1950s, both of which put paid to straw for thatch being part of the grain producing process. Wheat now has to be grown and processed specifically, or reed, often imported from Poland, might now be used instead of locally traditional materials. Thatch today is more often associated with rural housing owned by the wealthy, a situation with some precedence. As part of the late 18th century Romantic wish to recreate Arcadia, thatch became desirable amongst the rich with landowners, some built bucolic idylls such as the villages of Milton Abbas (Lord Milton moving the entire village as it spoiled his view) and, others, on a smaller scale, built the cottage orné, a picturesque interpretation of a rustic dwelling.

Thatching materials and technique

Water reed and wheat straw have become the predominant materials used for thatch, though straw

from other corn was used into the 20th century and rye straw is

still used for the ridges when thatching with water reed. Straw

can be used in two different ways. ‘Long straw’ consists of the

broken stems left after threshing which may or may not have the

butts aligned. ‘Combed wheat’ (Devon reed, wheat reed) has the

stems left unbroken by careful removal of the grain, it can then be

laid like water reed (hence the alternative names); all butts lie

Rev. William Winlaw’s Threshing Frame

downwards with little length exposed to the weather which gives it greater longevity than long straw. Combing in the late 18th and early 19th centuries was carried out by hand, with iron combs, or contrivances such as Rev. William Winlaws’s Threshing Frame but in the mid 19th century the reed comber, a device that attached to the drum of a threshing machine and removed grain and leaves without allowing the stems to enter was invented.

‘Long straw’ provides a finish that had been described as looking like it has been poured onto a building, wheat reed and combed wheat have been described as having a neat, close cropped finish.

Thatching with long straw in Hampshire

Some people argue that long straw represents the traditional style of thatching, as the evidence for

combed wheat only dates back to the implements mentioned above, however documentary evidence

from the Medieval period and the practical aspects of reaping with a hook, suggest that corn was cut

high leaving a long unbroken stem or the grain was cut from the stem after reaping. “Do not sell your

stubble or take it from the ground if you do not want it for thatching…” wrote Walter of Henley in the

1270s. In 1534 Master Fitzherbert wrote, “In some places they will shear their corn high, to the intent

to mow the stubble, either to thatch or to burn. In Somerset they mow their wheat very low, and all

the wheat they purpose to make thatch of, they do not thresh it but cut off the ears and bind it up in

sheaves and call it reeds”. Both these methods would leave a stem like that of combed wheat.

In preparation, combed wheat and water reed are both ‘butted’ on board to neaten the end of the bundle, and combed wheat is sprinkled with water and allowed to soak for a while. Long straw is thoroughly wetted before being ‘drawn’ from the waiting heap into bundles called ‘yealms’. A ‘yealm holder’, a Y shaped stick usually of ash, is used to transport yealms to the roof, combed wheat and water reed are usually carried up on the shoulder.

Working from the right of the roof to the left, larger bundles of thatch (‘bottles’ if long straw, ‘wadds’ if wheat reed and ‘bunches’ if water reed) are set at the eaves and gables. Traditionally thatch was laid so as to overhang the eaves by up to 3′ to ensure water was thrown away from the walls of the building, very important if the walls were of wattle and daub or other porous material. The bundles are tied to the rafters with tarred cord or held down by ‘sways’ which, though traditionally hazel, have more recently been made of iron. These may be pinned to the roof timbers with iron hooks or tied. Successive ‘courses’ of thatch are laid on the roof, either in 2½ – 3′ ‘lanes’ working up towards the ridge or working in sections horizontally around the roof and held down in a similar manner. Reed and combed wheat are constantly dressed into shape by butting upwards with a ‘leggett’, a wooden pad with ridges (combed wheat) or metal teeth (reed). Along the ridge, ‘ridge rolls’ are laid over which the final course of thatch is laid. Sedge or rye is used for the ridges of reed roofs as water reed lacks flexibility. The ‘liggers’ and spars that can be seen around the ridge of the roof hold the final courses of thatch down and also provide a decorative finish. Long straw roofs have liggers and spars around the eaves and gables, to stop the thatch lifting off in wind, though this might also be employed as a decorative device on combed wheat. The ridge may be left plain or a pattern cut in and it has been suggested that, in the past, families and regions had their own specific patterns of cutting and for liggers and spars. A ‘finial’ or ‘dolly’, often in the shape of a pheasant, may also be attached to the ridge, though some sources suggest there is no evidence of this before the 20th century. Long straw is finished by using a side rake with a combined beating and combing action, then trimmed at the eaves with a ‘hovers knife’ and tidied with hand shears. To trim the eaves of combed wheat an eaves or shearing hook is used, water reed should be laid in such a way as not to require trimming, though the sedge or rye ridge would be trimmed with

Lara Band 09/04/04

an eaves knife. The Museum has examples of many of the tools and other items mentioned above the collections.

There are some signs to look for that might suggest that a roof was originally thatched. Remains of flashing around a chimney at a point higher than the existing roofline might be indicative as when newly laid thatch can be 12″ – 15″ deep. Inside, marks from tarred cord around roof timbers would also suggest thatching. Irregularly spaced battens (or evidence left by nail holes for these) might indicate a roof was thatched, as battens for tiles were regularly spaced. Other signs may be a pitch of around 50˚ or more (though a steep pitch is not necessarily restricted to thatch) and a taller than usual chimney to kept the sparks well away from the thatch – but again this is by no means definitive.

Thatch was not restricted to covering buildings; ricks and other harvests of crops had to be protected from the elements. It is probable that many of the yealm holders and side rakes in the Museum thatching collections are related to this as the work was invariably done with long straw and these items would have been common on farms prior to the 1950s. A thatcher may have taken on this work, especially post 18th century, though many farmers or farm workers would have been competent at this sort of thatching. The 1847 -1849 ledger of William Garret, a thatcher from Trent, Dorset, shows the extent of the work carried out on farms. The bills he sent to farmers included work thatching hay and clover ricks, ‘mows’ of wheat, oats, barley, peas, beans, vetch, rye, flax; swede and ‘Magewersle’ graves. He also re-weatherproofed older ricks and cut and made his own spars.

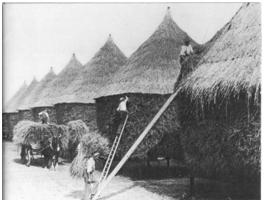

Rick thatching, from the first quarter of the 20th century

Other roofing materials

“where plenty of wood is, they cover them with tiles, otherwise with straw, sedge or reed, except some quarry of slate be near hand, from whence they have for their money much as may suffice them” William Harrison, 1587,described the roofing of domestic buildings in Britain

Tile

Originally more popular in Kent, (possibly due to closer links with the Low Countries, where tile was extensively made and used), the use of roofing tiles became more widespread from the 13th century. The growth of the industry went hand in hand with that of brick making and the manufacturing processes are similar; see the ‘introductions’ sheet on brick making. Tile is rarely found in excavations of pre-Mediaeval sites but the 1212 London building regulations, mentioned above under thatch, show it was definitely in use by then. Building accounts rarely mention tiles and the situation is further confused by the use of the term ‘tegulae’ to refer to brick, roofing tile and paving tile, though occasionally there may be references to ‘thaktyle’. Salzman in ‘Building in

Lara Band 09/04/04 Petersfield brick drying shed

England’ suggests that the paucity of references to tile might not mean it was not used but could mean that it was used extensively; i.e., unless another material is specified in accounts, it could be assumed that tile is being referred to. Tile certainly shows up extensively in the archaeological record from the Medieval period onwards, even though William Harrison doesn’t mention it when describing the roofing of England in 1587. Manorial accounts show large sums spent on repairing tiled roofs and an act was passed in 1477 regulating the manufacturing and size of tiles (10 ½” x 6 ¼” x 5/8“), which this suggests that early tiles were not of particularly good or consistent quality. Tiles were hung over wooden laths by wooden pegs, usually of oak and bedded on moss, (records show that this was usually collected by women). The lowest courses, or occasionally all the tiles, were pointed with mortar. With improvements in the manufacturing process in the 17th century tiles became the main competitor for thatch, though by the 18th century it had, like thatch, to compete with cheaper slate.

Shingle

Detail of the shingled roof of the beehive shelter in Bay leaf garden

Shingles, wooden ’tiles’ usually of oak, were another possible roof covering. With an average size of 2′ x 7″, they often had a rounded or pointed end to assist run off of water, and were thicker at the downward end. They did exist but appear not to have been very common, at least there is very little documentary evidence for the use of shingle. In 1248 Henry III ordered his rooms at Kennington and Woodstock to be shingled but in 1314 it was found to be cheaper to re-roof shingled roofs in manors held by Queen Margaret with stone slates or earthern tiles. Accounts

from Croydon show that in 1365 shingles were 10s per thousand compared to 4s – 5s 6d for tiles. By 1386 they cost 13s 4d showing a price rise that followed that of timber in general. Shingles were effectively priced out of the market by the 15th century, though when the apprentice system was formally set up in 1562, shinglers were mentioned so there must have been some demand. Shingles are often now only seen on church spires, where their lightness is an advantage.

Stone

‘Horsham slate’ or ‘Horsham slab’ is a type of sandstone once used as a roofing material through the Wealden areas of Sussex, south Surrey and Kent. Because of the weight it was often laid with large slabs of c.24″ at the eaves with gradually smaller ones laid towards the ridge. For further details of this see the ‘introductions’ sheet on building stone. In the 1796 in The City and County Purchaser and Builders Dictionary Richard Neve writes that it was ‘much used in parts of Sussex formerly, not only to heal or cover Churches and Chancels but some great Houses also’; it was generally restricted to larger houses because of the cost of the material and the cost of framing a roof strong enough to bear the weight.

Horsham shop

Slate

Slate was not widespread until improvements in rail transport made Welsh slate more accessible in the first part of the 19th century. However, roofing slate has been found in archaeological excavations in southern parts of Kent and Sussex, dating to the Medieval period, not only in relation to high status dwellings but also to farmsteads and

Lara Band 09/04/04

villages. Shipped along the coast from South Devon and Cornwall, the trade ceased at the turn of the 19th century. The 1212 building regulations don’t mention slate, which suggests it was not in use in London; a 1378 account from Cambridge does mention ‘a sclattere’ but this could also refer to a roofer using stone such as ‘Horsham slate’.

What’s up to every body, it’s my first pay a visit of this webpage; this web site carries remarkable and genuinely excellent information in support of readers.|