Columns that combine the strength of structural steel shapes and sitecast concrete have been used in buildings for many years. One type of composite column surrounds a steel wide-ß ange column with sitecast reinforced concrete. Another type consists of a steel pipe that is Þ lled with concrete. In a third type, a wide-ß ange column is inserted within the pipe before the concrete is added to create a higher loadbearing capacity.

Several recent high-rise buildings use very large steel pipe columns Þ lled with ver y-high-strength concrete to carry a major portion of both vertical and lateral loads.

These columns enable reductions of as much as 50 percent in the overall quantity of steel required for the building (Figure 11.90). In one such building, a 720-foot (200-m) ofÞ ce tower, four 10-foot-diameter (3-m) pipe columns Þ lled with 19,000-psi (131-MPa) concrete carry 40 percent of the gravity loads and a large proportion of the wind loads. There is no reinforcing or other steel inside the pipes except at certain connections that carr y ver y heavy loads. The potential advantages of composite columns in tall buildings include reduced steel usage, greater rigidity of the building against wind forces, and simpliÞ ed beam-column connections.

Industrialized Systems in Steel

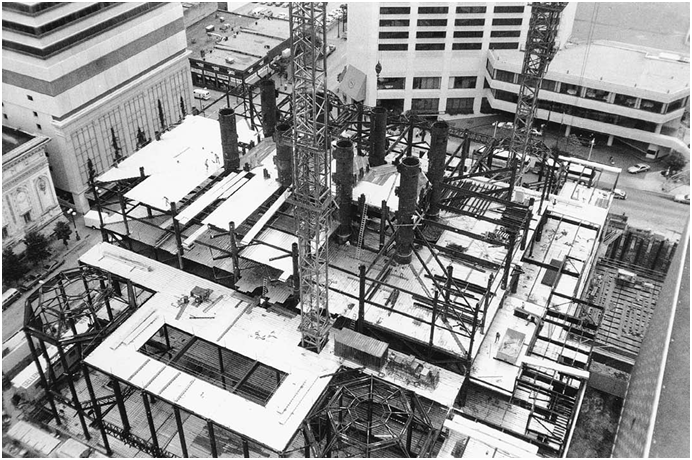

Figure 11.90

A core structure of eight large composite columns, each a concrete-filled pipe 7½ feet (2.3 m) in diameter, carries the majority of gravity and wind loads in this 44-story Seattle office building. The perimeter of the building is supported by smaller-diameter composite pipe columns. (Courtesy of Skilling Ward Magnusson Barkshire, Inc., Seattle, Washington)

0 thoughts on “Composite Columns”