Many people are becoming interested in pole building construction because they have heard or read that it is relatively cheap and simple. It is, but to understand exactly what it’s all about, we should start with a definition:

Pole construction is building in which the vertical, load-bearing members are poles embedded in the ground, and which must be long enough to support the roof. The diameter of the poles usually is about six inches at the top ends, and they are spaced much further apart than are the uprights in conventional frame construction. No excavation is necessary beyond digging holes for the poles, and there is no concrete or block foundation. The poles serve the triple function of foundation, bracing and framework, to which the floor (if any), walls and roof all are fastened.

Labor, time and materials all are saved in the pole framing method. Since lateral girts replace the conventional wall studs, and since fewer and longer pieces of lumber are used, the actual framework of the building can be completed quickly. This is a real advantage in bad weather, as the project can be placed under cover rapidly.

Pole buildings have been approved where light frame structures are prohibited because of fire hazard. Pole framing members are so widely separated that fire is unlikely to spread from one to the other. Pole construction is now recognized by all four U.S. model building codes.

Other advantages of pole construction are: It is relatively simple to build, and little sawing is necessary. No scaffolding or forms are required during construction, and a minimum of construction labor is needed. In buildings where the loads are relatively light or the spans rather short, lower (hence cheaper) grades of lumber may be used. If the pole holes are dug by hand, only simple hand tools—the kind found in almost any household—are needed.

There are further advantages to this kind of construction in that round timbers have two distinct advantages from the standpoint of strength.

A circular timber is 18 per cent stronger in bending resistance than a rectangular timber of similar grade. A round timber, in practically all cases, possesses a very high proportion of the basic strength of its species. This is because the knots have only half the limiting effect on strength in the natural, round timber form that they do in sawed sections. Tests have shown that full-size round timber poles develop practically the full bending strength of clear wood.

Another advantage of pole frame construction is its high resistance to wind forces, which results because the poles that support the building are firmly anchored in the ground.

Later in this book general basic directions are given on how to construct a pole building, and these are followed by some specific plans. Right now it’s enough to say that the poles are embedded in the ground, and they must be plumb.

The design of any pole building can be simple enough for unskilled persons to construct. Except for very small buildings, the step of setting the poles, however, is not a project for one person, the reason being that you have only two hands. For this step probably you should hire some

HOW IT GOES T O G E T H E R

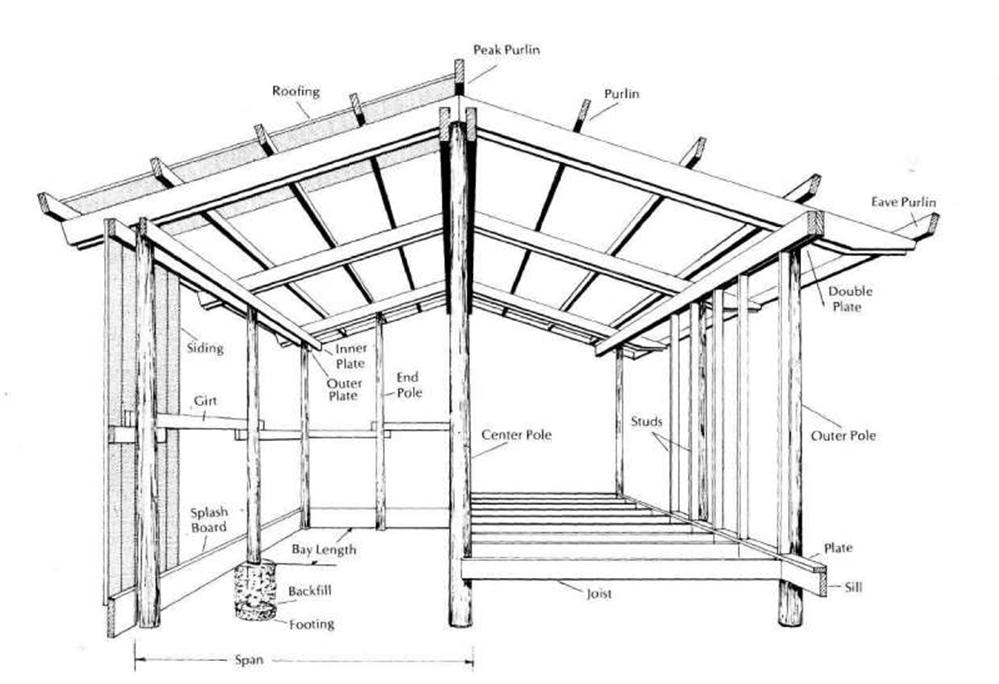

Left side of this cutaway view shows embedment of poles, attachment of rafter plates, rafters, purlins and roofing. Below are the splashboards, girts and siding. The right side is for a more finished building, as indicated by floor plate and joists and wall framing inside the poles. Eaves are given more overhang.

unskilled help, which you will supervise, or maybe you can find neighborly help, or rent a machine to lift the poles.

In Vermont Life Magazine (Summer 1956 issue) there’s a story of a pole-type barn-raising after a man’s barn burned and his cattle were without shelter. Neighbors helped on the barn (the women cooked), and in two days the poles and main timbers of the new, 80-cow barn were secured, and the majority of the roof was in place.

Once the poles are plumb, the next step is to nail (or bolt) the longitudinal beams to the poles, and make sure the structure is squared up. The roof rafters are connected to this frame, and then your exterior is completed—not forgetting to put on a roof!

What kinds of buildings lend themselves to pole construction? The list is long and includes just about any type of commercial building, such as a warehouse or light manufacturing plant. Then there are farm buildings of all kinds—cow barns, horse barns, cattle sheds, poultry houses, tool sheds and the like. There are homes, too.

Prefabricated pole buildings for commercial and farm use are obtainable from several manufacturers. The purpose of this book, however, is to show you how you can do it yourself economically. Later some plans will be pictured in detail, and these will include houses.

It was said earlier that pole construction is relatively simple, but bear in mind the operative word here is “relatively.” It would be cheating to give the impression it is as simple as making a sandbox for your youngster. But neither is it nearly as difficult (or expensive) as the conventional type of construction, which requires skilled labor, the extensive use of power tools, and more and costlier materials.

Pole building in varying forms is an age-old type of construction that dates back to the Stone Age.

Amos Rapoport in House Form and Culture says “There are cases where a way of life may lead to . . . a dwelling form related to economic activity rather than climate. For example, the Hidatsa of the Missouri valley were agriculturists from April to November, growing corn, greens and beans. During that period they lived in circular wooden houses 30 to 40 feet in diameter with 5-foot walls made of tree trunks and four central columns 14 feet high supporting rafters carrying branches.”

Rapoport goes on to comment on resistance to lateral forces, such as wind or earthquakes, that requires either rigidity or bracing.

“The Fiji islands provide a number of examples of methods of dealing with the lateral force, problem. In some areas the roofs are very simple and supported by central poles as well as peripheral columns. Since these poles are buried deep in the ground, the building acts as a rigid frame, although the flexibility of the members themselves assures some flexibility.”

In pole construction the poles actually have an inherent ability to resist wind uplift, especially if the roof framing is very securely attached to them. In areas where hurricanes are expected, the value of this large resistence to uplift that is a part of pole construction should be considered seriously.

Why is there so much current interest in pole construction? There seems to be a batch of good reasons:

1. A limited amount of grading is required, and no excavation beyond digging the pole holes. Thus it can be accomplished without butchering the immediate area, and with a minimum disturbance of the natural surroundings such as tree roots and top soil.

2. Pole construction offers a way to lower building costs by utilizing, if desired, steep hillside locations which

present many problems for more conventional construction. There are no delays, either, in waiting for cement foundations to cure, for there are none.

3. As inflation causes the costs of building materials and labor to climb, there is a very real need for many people to find ways to build more cheaply than before. Pole methods allow such savings.

4. Ever since World War II there has been an ever-increasing interest in self-help. Not only are there many practical advantages to “doing it yourself,” but there is a very tangible glow of pride and satisfaction when one completes his own project.

5. With the back-to-the-land movement increasing every year, many people are rejecting expensive and conspicuous life styles. They want and have only the simple tools for living, and are choosing to live in many ways as their ancestors did.

All of this adds up to the reason why pole construction may be the very thing to plan on, whether it is for a home or some other building that you need.

Very little has been published to date on pole construction. In fact it has been said that “the literature is nonexistent.” This is not quite true, for there are some few publications by wood products associations, which have been consulted here, and which are listed in the references at the back of this book.

The modern use of treated poles in the construction of restaurants, churches, schools, vacation cottages and homes began quite recently and as a West Coast phenomenon, gaining impetus with the construction in 1958 of a pole residence in California. Modern methods were learned through the experience of utility and outdoor advertising companies. At the time there was resistance both from lending sources and building code reviewers, but since then enthusiasm for the many advantages of pole construction has mushroomed.